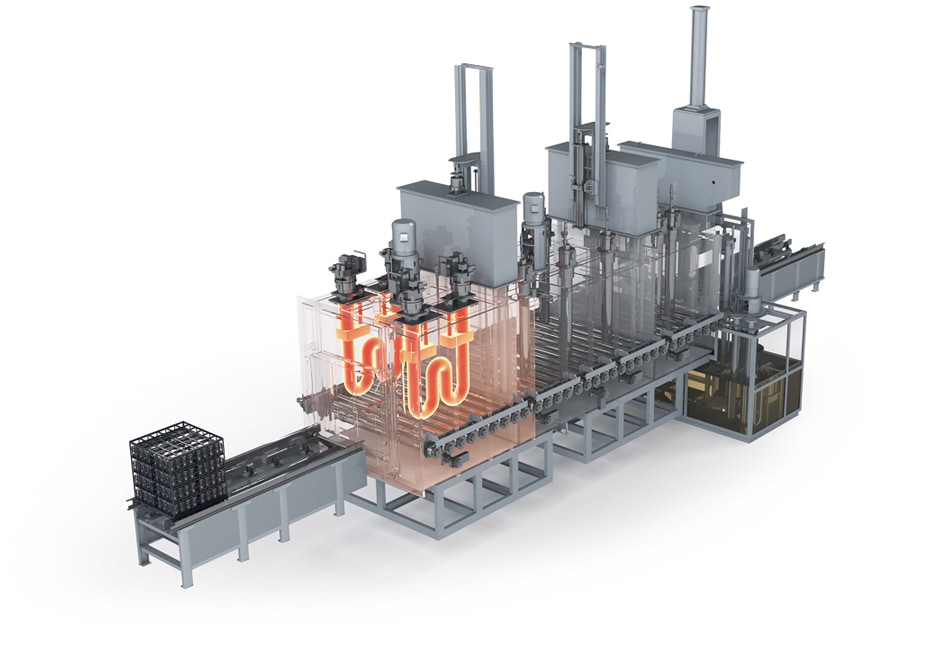

Unleash the power of precision and efficiency with the Brahmo Tech Industrial Furnace, a cutting-edge solution from the pioneers at Brahmo Technologies Private Limited. Engineered for reliability and performance, our industrial furnace is designed to meet the rigorous demands of diverse industrial applications, setting new standards in high-temperature processing. Read more

The combustion heating system is equipped with regeneration gas burners as standard equipment, which enables effective use of exhaust heat to reduce energy consumption. In addition, we conduct simulation analysis of atmospheric gases in furnaces to optimize the locations and number of gas inlets. We are determined to reduce energy usage and environmental loads.

High-functionality, fine-porous heat insulation material is used for outer walls of industrial furnaces. This minimizes heat transfer and prevents loss of heat energy (from the interior to the exterior of the furnace). In addition, the safety of the work environment is enhanced because the surface temperatures of furnace walls are reduced.

Ceramic fibers with superior heat insulation capacity and low bulk density are used for inner walls of furnaces. Applying a combination of optimal heat insulation materials to both the interior and exterior of the furnace body increases heating efficiency and significantly reduces energy costs. Using heat insulation materials with low bulk density reduces heat storage and significantly reduces the equipment setup time.

| Specifications | Descriptions |

|---|---|

| No Specifications | |

Brahmo offers a wide range of industrial equipment to satisfy the industrial needs of different aspects of the pharma industries.